You are in:

300m

First

Service |

Ford

Anglia 105E - 300 Mile (500 km) First Check and Service

Schedule

It is impossible

to over emphasise the importance of correct

lubrication, inspection and running adjustments,

if you wish to obtain the best level of service

from your Ford Anglia and Ford Prefect. At the

first 300 Miles (500 km) it is advisable to have

a “1000 Mile Service” carried out on

the car, with particular attention to the first

six points. (In the later Handbooks and Manuals,

this periodic service was extended to the first

500 miles).

The 300 Mile service incorporates:

(Key: This Colour = Daily Service items, This Colour

= Weekly

Service items, This Colour = 1000 Mile

Service Items)Change the Engine Oil

Change the Engine Oil Filter Element

Check Cylinder Head Bolts

Check and Adjust Valve Clearances (if

necessary)

Check the Wheel Nuts

Check the Clutch Adjustment at Operating Cylinder

Check the Radiator Level

Check the Petrol Level in the Tank

Check the Windscreen is Clean

Check the Battery Electrolyte Level

Check the Brake and Clutch Fluid Reservoir Levels

Check the Operation of all Lights

Check the Tyre Pressures

Check the Gearbox Oil Level

Check the Rear Axle Oil Level

Check the Steering Box Oil Level

Check

the Fan Belt Adjustment

Check the Clutch Adjustment at Operating Cylinder

Check the Windscreen Washer Level (where

fitted)

Check the Seat Belts for Security and Wear (where

fitted)

Lubricate all Grease Gun Points (L1 - L5)

Lubricate Linkages and Locks

Lubricate the Distributor

|

Clean the Oil Filler Cap

The oil filler cap also acts as an engine

ventilator and it is advisable to remove any

accumulation of foreign matter from the gauze,

when changing the engine oil.To clean the dry gauze type

cap it is only necessary to wash this in petrol

or paraffin and then dip in engine oil, shaking

out the surplus. Although a small job, this is

quite important as Ford engines do breathe quite

heavily.

|

|

Change

the Engine Oil

This service item covers both this item and the

next item, which is to drain the oil and change

the oil filter element.Check the oil with the dipstick. If the

oil on the dipstick appears dirty for any reason

before this mileage is reached, the engine should

be refilled with clean new oil and the filter

element replaced.

Place

a suitable container under the sump drain plug.

Do not overlook the fact that there may be up to

4 ½ pints of oil in the sump, so use a drain pan

of sufficient size to hold this quantity of oil.

Remove the sump drain plug. The engine oil will

drain out more easily when warm and, at the same

time, will tend to remove any foreign matter

present in the sump.

When

all of the oil has been drained away, replace the

drain plug. A good quality flushing oil may be

used in the engine, but in NO CIRCUMSTANCES

SHOULD PARAFFIN BE USED TO FLUSH OUT THE

CRANKCASE.

Replace

the oil filter element (as detailed below). Pour

the appropriate quantity of correct grade oil in through the filler

neck, run the engine for a short while, allow to

stand, and then check the oil level on the dipstick,

topping up as required.

Warning –

Do not pour old oil down the sink or into any

water drain. Place it in an old container and

dispose of it at your local Council Oil Recycling

Centre.

|

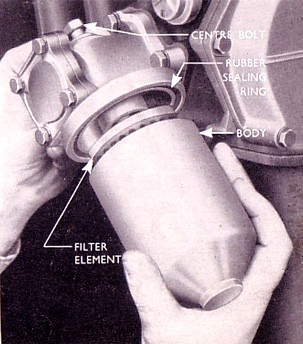

Change the Engine Oil Filter

Element

The oil filter

is fitted direct onto the cylinder block, no

connecting pipes to the engine being required. To

change the element, first drain the oil (as

above) and undo the hexagon headed bolt retaining

the filter unit to the cylinder block, and

withdraw the filter assembly. Withdraw the filter

element from the casing and replace it with the

new element.A new rubber sealing ring

is supplied with each element. Remove the

existing ring, then locate the new ring in the

groove at four diametrically opposite points. Do

not fit the gasket at one point and then work it

round the groove, as the rubber may stretch, thus

leaving a surplus, which could cause an oil leak.

Refit the filter

assembly to the cylinder block and retighten the

bolt.

|

|

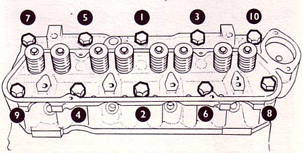

Check Cylinder Head Bolts

To check the cylinder head bolts, remove the

valve rocker cover by undoing the four retaining

screws. Be careful not to damage the rocker cover

gasketThe cylinder head bolts should be

tightened at this mileage in the sequence

illustrated opposite.

Take care not to over tighten the

cylinder head bolts as this will only impose

excessive strain. If possible, use a torque

wrench and tighten the bolts to 65-70 lb/ft

When replacing the

rocker cover ensure that the gasket is correctly

positioned on the cylinder head to avoid oil

leaks

|

|

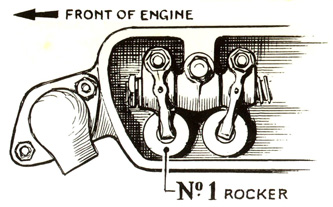

Check

the Valve Clearances and Adjust (if

necessary)

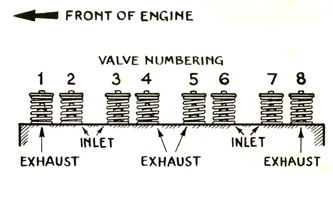

Open the

bonnet and listen to the engine carefully. If

there is a clattering sound from the top of the

engine, and the sound increases both in loudness

and noise as the engine speed is increased, then

it is best to check and adjust the valve

clearances. Each cylinder has a pair of valves;

one inlet and one exhaust, and each valve is

operated by its rocker arm.

To check or adjust the valve clearances, remove

the valve rocker cover by undoing the four

retaining screws. Be careful not to damage the

rocker cover gasket.The valve clearance

adjusting screws will then be exposed, and the

clearance should be adjusted to 0.010 in (0.254

mm) for the inlet valves and 0.017 in (0.432 mm)

for the exhaust valves, with the engine at normal

operating temperature.

In

order to ensure that each valve is fully closed,

check as follows:-

|

Valves Open

1 and 6 .. .. .. .. .. .. .. .. .. .. .. .. .. ..

.. .. .. .. .. .. .. .. ..

3 and 8 .. .. .. .. .. .. .. .. .. .. .. .. .. ..

.. .. .. .. .. .. .. .. ..

2 and 4 .. .. .. .. .. .. .. .. .. .. .. .. .. ..

.. .. .. .. .. .. .. .. ..

5 and 7 .. .. .. .. .. .. .. .. .. .. .. .. .. ..

.. .. .. .. .. .. .. .. ..

Exhaust Valves Nos 1, 4, 5 and 8 |

Valves to Adjust

3 and 8

1 and 6

5 and 7

2 and 4

Inlet Valves Nos 2, 3, 6 and 7 |

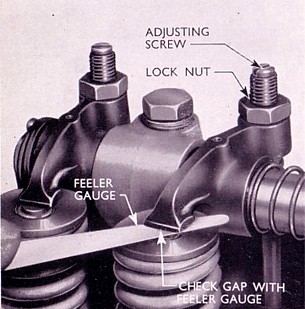

| To adjust a rocker, slacken

off the adjusting screw locknut and insert a

feeler blade between the toe of the rocker and

the valve end. Turn the adjusting screw until the

correct clearance has been obtained and tighten

the locknut. Recheck the gap after tightening the

locknut to make sure it hasn’t moved. When replacing the rocker

cover ensure that the gasket is correctly

positioned on the cylinder head to avoid oil

leaks.

|

|

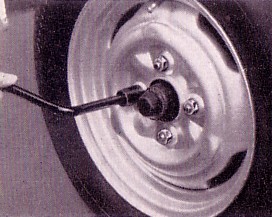

Wheel Nuts

It is good practise to check all of the Wheel

Nuts on a regular basis for tightness. Do not use

any sort of extension bar, as ordinary pressure

exerted on the handle of the wheel brace supplied

with your vehicle is sufficient. |

|

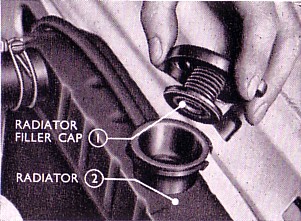

Check the Radiator Level

The cooling system is pressurised by means of a

spring loaded pressure radiator cap. If the

vehicle has been running and is hot, allow it to

cool down before attempting to remove the

radiator cap. Warning

– Do not remove the radiator cap when the

water is near boiling point, as this may cause

water and steam to be blown back out of the

filler neck at pressure, possibly causing

personal injury.

Remove the

radiator filler cap slowly, by pushing down

slightly and twisting it to release it. Check the

water level in the top of the radiator. Top up as

necessary with the correct anti-freeze / water

mixture, to approximately one inch (25 mm) below

the bottom of the filler to allow for expansion

of the coolant as the engine warms up. Once the

radiator has been topped, the radiator cap can be

replaced.

|

|

Check the

Petrol Level in the Tank

Before any journey ensure that the level of fuel

in the tank is sufficient for immediate needs.

This can easily be ascertained by switching on

the ignition, and observing the reading of the

fuel gauge fitted on the instrument panel. It is

advisable not to let the level in the petrol tank

fall too low as any dirt or particles within the

tank / petrol will find their way into the fuel

lines. If there is insufficient fuel for

immediate needs then the petrol tank needs to be

topped up. Check

the Windscreen is Clean

To ensure you have good visibilty whilst driving,

clean your windscreen with a clean dry cloth and

an appropriate vehicle glass cleaner.

|

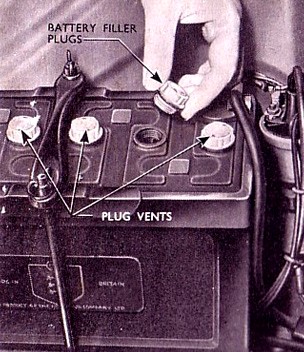

Check the Battery

Electrolyte Level

The battery is

accessibly located under the bonnet, within the

engine compartment. Remove the filler caps and

check that the electrolyte in each cell is 1/4 to

3/8 in (6.35 to 9.525 mm) above the tops of the

plates. If below this level add distilled water

as necessary. (In cold weather the distilled

water should only be added immediately before

running the engine, so that when the generator is

charging, the water and electrolye will mix and

prevent freezing.) The filler caps can now be

refitted. Keep the battery filler

caps and battery connections tight and the top of

the battery clean.

A

coating of petroleum jelly will protect the

battery terminals. Occasionally check the battery

clamp to ensure that the mounting wings nuts are

tight and the battery is still secure in the

battery tray.

Excessive

use of distilled water by the battery is usually

an indication of an unduly high

generator-charging rate and you should consult an

Auto Electrician or your Authorised Ford Dealer

and have the charging system checked.

|

|

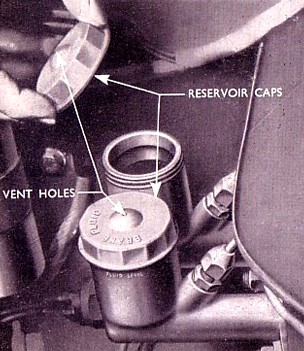

Check the Brake and Clutch

Fluid Reservoir Levels

The brake and clutch fluid reservoirs are located

in the engine compartment on the driver’s

side of the car and are integral with their

master cylinders. When checking or replenishing

the system wipe the sides of the reservoirs and

caps with a clean dry cloth to prevent any dirt

entering the system. Do not use a cloth that is

greasy or has been soaked in petrol or paraffin

etc. Remove each cap by unscrewing it and

top up if necessary to the level indicated on the

reservoir casing (approximately 5/8 in (16mm)

from the rim). Use only the correct brake fluid, obtainable from your

Authorised Ford Dealer.

Warning

– MINERAL OILS MUST NOT BE USED IN ANY

CIRCUMSTANCES FOR TOPPING UP THE RESERVOIRS.

|

|

Check the Tyre Pressures

It is necessary to keep the tyre pressures at the

specified figures, checking the pressures at

least once a week is recommended. It's not always

apparent that air is being lost, but it generally

escapes at the rate of up to two pounds of air

every month. More air is usually lost during warm

weather, so more regular checks are needed when

temperatures rise. Incorrect tyre pressures or

excessive wear can adversely affect the steering

and braking of the car. The tyre pressure should

be checked before a run whilst the tyres are

cold, as a hot tyre will give a higher reading.

If the tyres are checked hot, do not, in any

circumstances, bleed off this increase in

pressure.

The air pressure in the tyres has a pronounced

effect on the action of the brakes, as well as

the correct operation of the front suspension and

steering gear. |

|

To check the

pressure of a tyre, remove the valve cap and

press a suitable tyre gauge firmly ito place. If

necessary sufficient air should be added to bring

the tyre pressure up to the amount specified. Do

not forget to check the pressure of the spare

wheel.

Do not forget to refit the valve cap. Unequal or insufficient

pressure results in rapid wear, uneven braking

and heavy steering.

The correct tyre

pressures are:

Anglia Saloon - 22lb/sq in (1.54 kg/sq cm) front

and rear

Anglia Estate – 24 lb/sq in (1.69 kg/sq cm)

front and 30 lb/sq in (2.11 kg/sq cm) rear

Anglia 5cwt Van - 24 lb/sq in (1.69 kg/sq cm)

front and rear

Anglia 7cwt Van - 24 lb/sq in (1.69 kg/sq cm)

front and 30 lb/sq in (2.11 kg/sq cm) rear

More information about tyres is contained in the General

Maintenance for Wheels and Tyres Page

Check the

Operation of all Lights

Operate all of the lights one at a time and check

that they operate correctly and that there are no

blown bulbs. As well as it being unsafe to drive

without operating lights, it is also an offense

in the UK.

To replace any of the bulbs, follow the steps at

the General Maintenance for

Lights

Page.

|

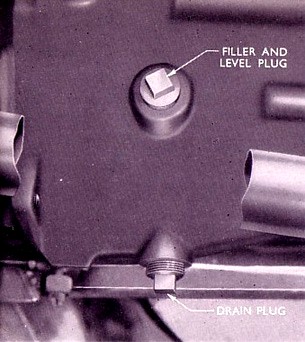

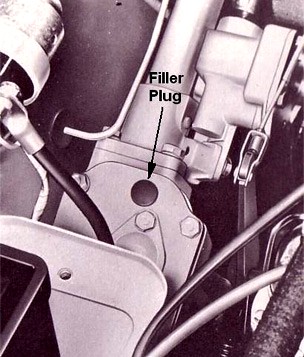

Check the Gearbox Oil Level

With the car

standing on level ground, remove the combined

filler and level plug, which is located on the

side of the gearbox. Check the oil level, which

should be level with the bottom of the filler

plug hole. If required, top up with Extreme Pressure Gear Oil. The oil may be added by

means of a suitable gun through the combined

level and filler plug until the level reaches the

bottom of the filler plug hole. Replace the

filler plug and tighten securely.The

oil in the gearbox should be maintained to the

level of the filler plug at all times.

Insufficient oil will accelerate wear on the

gearbox parts, whilst too high an oil level may

result in the oil passing into the clutch housing

with consequent ill effects on the clutch facings

|

|

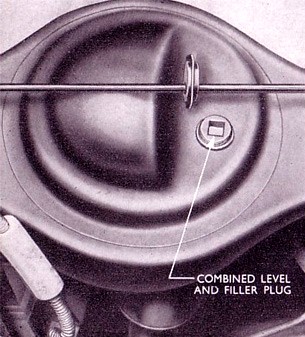

Check the Rear Axle Oil

Level

With the car standing on level ground, remove the

combined filler and level plug, which is located

halfway up the axle (on earlier cars there is

also a drain plug located in the bottom of the

axle.) Check the oil level, which should be level

with the bottom of the filler plug hole. If

required top up with the correct Grade of Oil until the level reaches

the filler plug hole.NOTE

– Only Hypoid and not

ordinary gear oil is to be used in the rear axle.

Replace the filler

plug and tighten securely. Periodically check the

tightness of the filler plug.

|

|

Check the Steering Box Oil

Level

With the car standing on level ground, remove the

rubber plug on top of the steering box. Check the

oil level, which should be level with the filler

plug hole. If required top up with Extreme Pressure Gear Oil until the level reaches

the filler plug hole.Replace the rubber plug.

The Steering Gear is of the worm and nut and

apart from the periodic lubrication described

above, requires adjustment and attention only at

fairly long intervals

|

|

|

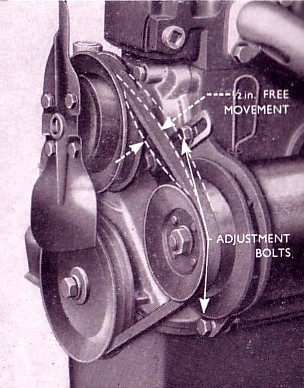

Check the Fan Belt

Adjustment

The same V-Shaped belt drives both the generator

and water pump. The belt adjustment is correct

when, as it is pushed and pulled at a point

midway between the generator and water pump

pulleys, the total movement of the belt does not

exceed ½ in (12.7mm). A loose belt causes slip

on the pulleys, while excessive tightness results

in wear on the generator and water pump bearings

and the belt itself.To adjust the fan belt

tension, loosen the two generator lower mounting

bolts, one at the front and one at the rear, then

loosen the adjustment locking screw at the front

of the generator. This will allow the generator

to be moved outwards, the adjustment screw

sliding in the slotted arm.

When the correct

tension is obtained, tighten all three bolts

securely.

|

|

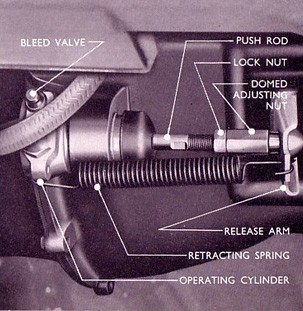

Check the Clutch Adjustment

At Operating Cylinder

The amount of free travel on the clutch release

arm should be checked and adjusted if necessary.

The clearance between the end of the clutch

operating rod adjusting nut and the clutch

release arm should be 1/16 in (1.6mm)

Compensation for wear is easily made by adjusting

the length of the clutch operating rod. To obtain

the correct clearance, disconnect the release arm

return spring, slacken the operating rod locknut

and turn the domed adjusting nut at the end of

the push rod clockwise to increase the free

movement and anti-clockwise to reduce it.After

making the adjustment, ensure that the locknut is

tightened and the return spring is re-located.

|

|

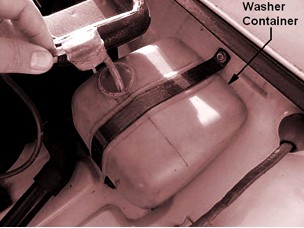

Check the Windscreen Washer

Level (where fitted)

The windscreen washer container is located on the

left hand side of the engine compartment on the

bulkhead next to the heater.The

container is made of an opaque plastic and so you

should be able to see whether the windscreen

washer fluid needs topping up. If the level is

low, remove the cap from the container and fill

with a suitable screen wash solution. Refit the

container cap.

|

Check the

Seat Belts for Security and Wear (where

fitted)

Check along the length of the webbing on each

belt to see if there are any nicks or tears in

the material. Sit in the vehicle and then test

the buckle, making sure that it opens and closes

smoothly and does not stick. Gently pull on the

closed buckle to see if it is secure. Check that

the seat belt adjustment works correctly by

adjusting the belt to see that the belt moves

smoothly through the adjuster and does not snag

on anything. (Remember to re-adjust it to your

needs before using the car.)Warning

- If the belts look defective in

anyway, or you are unsure about what to look for,

have the belts checked by your Authorised Ford

Dealer or a trained Mechanic. Do not take risks.

Your life may depend on the security of the seat

belts.

Lubricate

all Grease Gun Points

It is essential that a high-pressure grease gun

be used to force a good quality grease in to

parts equipped with the conical shaped non-return

lubricators (grease nipples).

A

Grease Gun can be purchased from your Authorised

Ford Dealer. To fill the grease gun, remove the

cap and plunger, pack the body with grease

solidly excluding as much air as possible, then

replace the cap and plunger. Use a high grade

grease for all bearing surfaces.

It

is important that dirt and old grease are cleaned

from around the lubricators before applying a

grease gun to them.

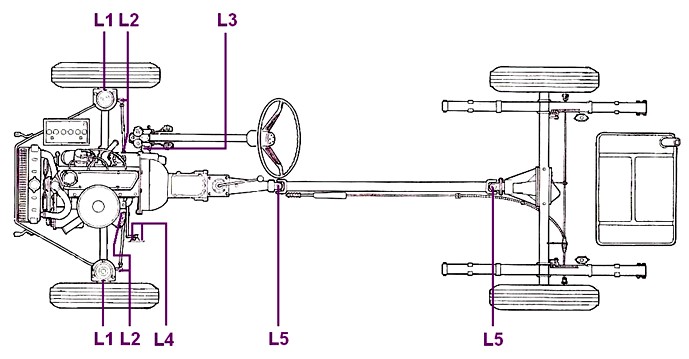

The

lubrication Chart below shows the approximate

position of the lubricators.

For convenience

the grease gun points are also briefly described

separately after the chart.

|

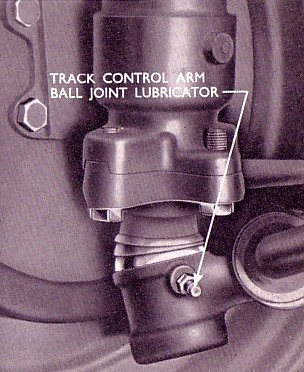

Grease Gun Point –

Track Control Arm - (L1)

The ball joint at the outer end of each track

control arm support is fitted with a lubricator,

which can be reached from beneath the front of

the car, forward of the front suspension cross

tube.

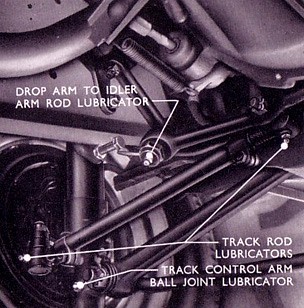

Grease

Gun Point – Track Rods - (L2)

The ball joint at each end of the right and left

hand track rods are fitted with grease gun

lubricators.

|

|

Grease Gun Point –

Steering Arm to Idler Arm Rod - (L3)

A lubricator is fitted at each end of this rod to

facilitate lubrication at the ball joints.

Grease Gun

Point – Idler Arm (L4)

The upper support bearing on the idler arm

bracket has a lubricator fitted in the centre of

the retaining cap nut

|

|

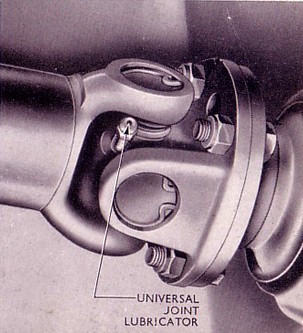

Grease Gun Point –

Universal Joints - (L5)

Each universal joint is fitted with a lubricator

at the centre of the spider. Apply a gun

containing SAE 250 oil or multi purpose lithium

base grease at these points and lubricate as

necessary |

|

Lubricate

Linkages and Locks

A few drops of light oil should be applied to the

accelerator linkage bearings, hand brake

clevises, bonnet hinges, door hinges and locks,

etc.The

door locks may be lubricated through a small hole

in the rear edge of each door, above the lock.

Make sure that all runs or drips of oil that are

visible on the doors are wiped away with a clean

dry cloth to prevent the soiling of clothing when

entering the vehicle.

|

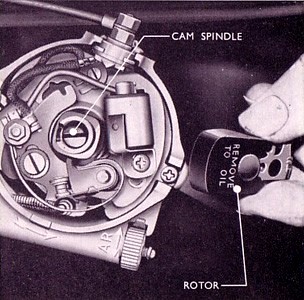

Lubricate the Distributor

Release the two spring clips and remove the

distributor cap and rotor. Apply one or two drops

of engine oil at the cam retaining screw and

spindle to lubricate the distributor shaft

bearings.Apply a thin film of petroleum jelly to

the contact breaker cam and lubricate the contact

breaker pivot post with a small film of engine

oil, ensuring that the contact breaker points are

not contaminated. |

|

Information taken from Various Ford

Anglia Instruction Books and Handbooks.

Warning -

The Health and Safety bit.

Please note your health may be at

risk if you do not take sensible safety

precautions. Never work under an unsupported

vehicle, do not take shortcuts. If you feel that

the task is beyond your capabilities, then employ

the services of a trained professional. The Owner

of this Website nor the author cannot be held

responsible for any accidents or injury arising

from advice given on this webpage. Safety advice

can be obtained from the RoSPA.

|

|

|