You are in:

1,000m

Check

and Service |

Ford

Anglia 105E - 1,000 Mile (1,600 km) Check and

Service Schedule

| It is impossible

to over emphasise the importance of correct

lubrication, inspection and running adjustments,

if you wish to obtain the best level of service

from your Ford Anglia. Every 1,000 miles (1,600

km) the following work, mainly lubrication,

should be carried out. (This periodic service was

extended to every 2,500 miles). The 1,000 / 2,500 Mile service also

incorporates:

(Key: This Colour = Daily Service items, This Colour

= Weekly

Service items)

Check

the Engine Oil

Level

Check the Radiator

Level

Check the Petrol

Level in the Tank

Check the Windscreen is Clean

Check the Battery Electrolyte Level

Check the Brake and

Clutch Fluid Reservoir Levels

Check the Operation

of all Lights

Check the Tyre

Pressures

Check the Gearbox Oil Level

Check the Rear Axle Oil Level

Check the Steering Box Oil Level

Check the Fan Belt Adjustment

Check the Clutch Adjustment at Operating Cylinder

Check the Windscreen Washer Level (where fitted)

Check the Seat Belts for Security and Wear (where

fitted)

Lubricate all Grease Gun Points (L1 - L5)

Lubricate Linkages and Locks

Lubricate the Distributor

|

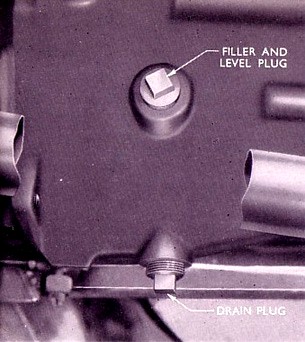

Check the Gearbox Oil Level

With the car

standing on level ground, remove the combined

filler and level plug, which is located on the

side of the gearbox. Check the oil level, which

should be level with the bottom of the filler

plug hole. If required, top up with Extreme Pressure Gear Oil. The oil may be added by

means of a suitable gun through the combined

level and filler plug until the level reaches the

bottom of the filler plug hole. Replace the

filler plug and tighten securely.The

oil in the gearbox should be maintained to the

level of the filler plug at all times.

Insufficient oil will accelerate wear on the

gearbox parts, whilst too high an oil level may

result in the oil passing into the clutch housing

with consequent ill effects on the clutch facings

|

|

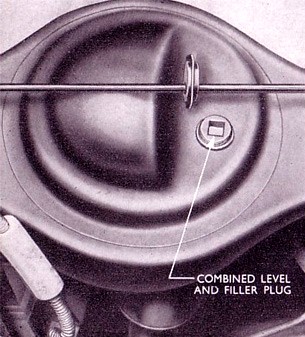

Check the Rear Axle Oil

Level

With the car standing on level ground, remove the

combined filler and level plug, which is located

halfway up the axle (on earlier cars there is

also a drain plug located in the bottom of the

axle.) Check the oil level, which should be level

with the bottom of the filler plug hole. If

required top up with the correct Grade of Oil until the level reaches

the filler plug hole.NOTE

– Only Hypoid and not

ordinary gear oil is to be used in the rear axle.

Replace the filler

plug and tighten securely. Periodically check the

tightness of the filler plug.

|

|

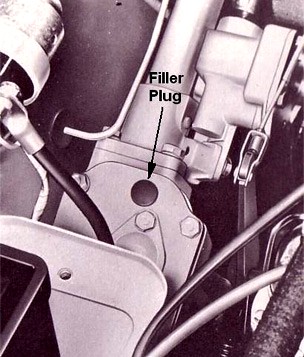

Check the Steering Box Oil

Level (Anglia)

With the car standing on level ground, remove the

rubber plug on top of the steering box. Check the

oil level, which should be level with the filler

plug hole. If required top up with Extreme Pressure Gear Oil until the level reaches

the filler plug hole.Replace the rubber plug.

The Steering Gear is of the worm and nut and

apart from the periodic lubrication described

above, requires adjustment and attention only at

fairly long intervals

|

|

|

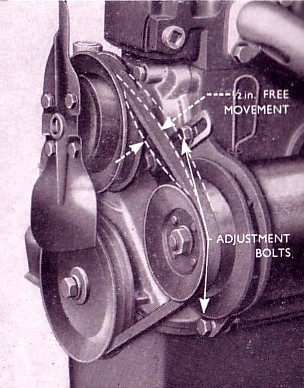

Check the Fan Belt

Adjustment

The same V-Shaped belt drives both the generator

and water pump. The belt adjustment is correct

when, as it is pushed and pulled at a point

midway between the generator and water pump

pulleys, the total movement of the belt does not

exceed ½ in (12.7mm). A loose belt causes slip

on the pulleys, while excessive tightness results

in wear on the generator and water pump bearings

and the belt itself.To adjust the fan belt

tension, loosen the two generator lower mounting

bolts, one at the front and one at the rear, then

loosen the adjustment locking screw at the front

of the generator. This will allow the generator

to be moved outwards, the adjustment screw

sliding in the slotted arm.

When the correct

tension is obtained, tighten all three bolts

securely.

|

|

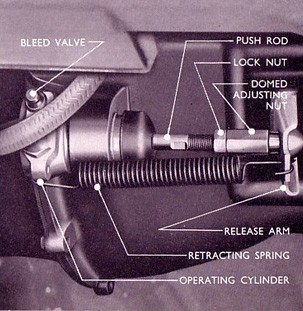

Check the Clutch Adjustment

At Operating Cylinder

The amount of free travel on the clutch release

arm should be checked and adjusted if necessary.

The clearance between the end of the clutch

operating rod adjusting nut and the clutch

release arm should be 1/16 in (1.6mm)

Compensation for wear is easily made by adjusting

the length of the clutch operating rod. To obtain

the correct clearance, disconnect the release arm

return spring, slacken the operating rod locknut

and turn the domed adjusting nut at the end of

the push rod clockwise to increase the free

movement and anti-clockwise to reduce it.After

making the adjustment, ensure that the locknut is

tightened and the return spring is re-located.

|

|

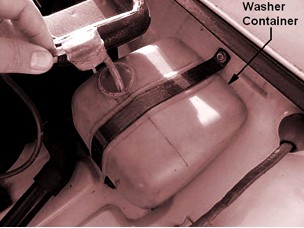

Check the Windscreen Washer

Level (where fitted)

The windscreen washer container is located on the

left hand side of the engine compartment on the

bulkhead next to the heater.The

container is made of an opaque plastic and so you

should be able to see whether the windscreen

washer fluid needs topping up. If the level is

low, remove the cap from the container and fill

with a suitable screen wash solution. Refit the

container cap.

|

Check the

Seat Belts for Security and Wear (where

fitted)

Check along the length of the webbing on each

belt to see if there are any nicks or tears in

the material. Sit in the vehicle and then test

the buckle, making sure that it opens and closes

smoothly and does not stick. Gently pull on the

closed buckle to see if it is secure. Check that

the seat belt adjustment works correctly by

adjusting the belt to see that the belt moves

smoothly through the adjuster and does not snag

on anything. (Remember to re-adjust it to your

needs before using the car.)Warning

- If the belts look defective in

anyway, or you are unsure about what to look for,

have the belts checked by your Authorised Ford

Dealer or a trained Mechanic. Do not take risks.

Your life may depend on the security of the seat

belts.

Lubricate

all Grease Gun Points

It is essential that a high-pressure grease gun

be used to force a good quality grease in to

parts equipped with the conical shaped non-return

lubricators (grease nipples).

A

Grease Gun can be purchased from your Authorised

Ford Dealer. To fill the grease gun, remove the

cap and plunger, pack the body with grease

solidly excluding as much air as possible, then

replace the cap and plunger. Use a high grade

grease for all bearing surfaces.

It

is important that dirt and old grease are cleaned

from around the lubricators before applying a

grease gun to them.

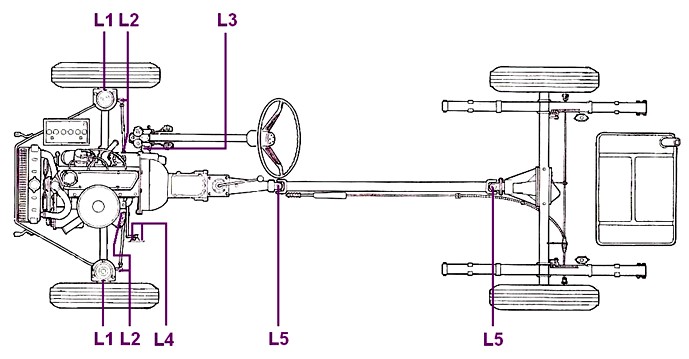

The

lubrication Chart below shows the approximate

position of the lubricators.

For convenience

the grease gun points are also briefly described

separately after the chart.

|

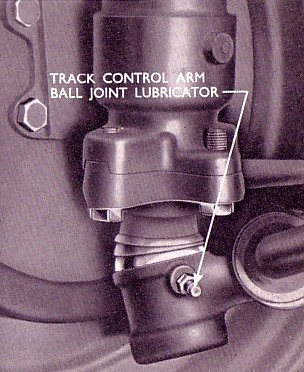

Grease Gun Point –

Track Control Arm - (L1)

The ball joint at the outer end of each track

control arm support is fitted with a lubricator,

which can be reached from beneath the front of

the car, forward of the front suspension cross

tube.

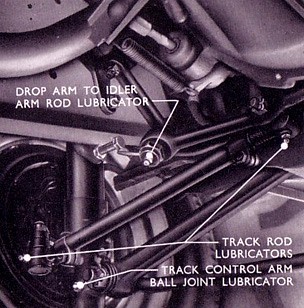

Grease

Gun Point – Track Rods - (L2)

The ball joint at each end of the right and left

hand track rods are fitted with grease gun

lubricators.

|

|

Grease Gun Point –

Steering Arm to Idler Arm Rod - (L3)

A lubricator is fitted at each end of this rod to

facilitate lubrication at the ball joints.

Grease Gun

Point – Idler Arm (L4)

The upper support bearing on the idler arm

bracket has a lubricator fitted in the centre of

the retaining cap nut

|

|

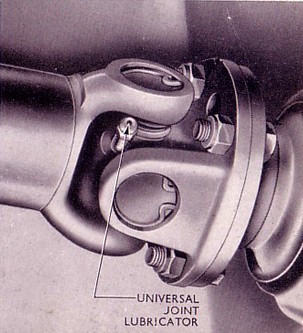

Grease Gun Point –

Universal Joints - (L5)

Each universal joint is fitted with a lubricator

at the centre of the spider. Apply a gun

containing SAE 250 oil or multi purpose lithium

base grease at these points and lubricate as

necessary |

|

Lubricate

Linkages and Locks

A few drops of light oil should be applied to the

accelerator linkage bearings, hand brake

clevises, bonnet hinges, door hinges and locks,

etc.The

door locks may be lubricated through a small hole

in the rear edge of each door, above the lock.

Make sure that all runs or drips of oil that are

visible on the doors are wiped away with a clean

dry cloth to prevent the soiling of clothing when

entering the vehicle.

|

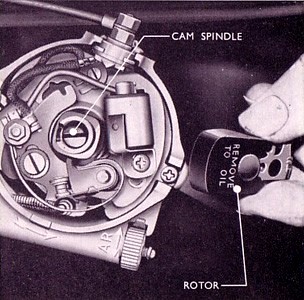

Lubricate the Distributor

Release the two spring clips and remove the

distributor cap and rotor. Apply one or two drops

of engine oil at the cam retaining screw and

spindle to lubricate the distributor shaft

bearings.Apply a thin film of petroleum jelly to

the contact breaker cam and lubricate the contact

breaker pivot post with a small film of engine

oil, ensuring that the contact breaker points are

not contaminated. |

|

Information taken from Various Ford

Anglia Instruction Books and Handbooks.

Warning -

The Health and Safety bit.

Please note your health may be at

risk if you do not take sensible safety

precautions. Never work under an unsupported

vehicle, do not take shortcuts. If you feel that

the task is beyond your capabilities, then employ

the services of a trained professional. The Owner

of this Website nor the author cannot be held

responsible for any accidents or injury arising

from advice given on this webpage. Safety advice

can be obtained from the RoSPA.

|

|

|