You are in:

GPO

Vans |

Ford

Anglia 307E Van Photo's - GPO - Album No 2

Shown below

is a copy of a GPO Instruction detailing the Ford Anglia

Van.

| TELECOMMUNICATIONS

INSTRUCTION |

J TRANSPORT AND

MECHANICAL AIDS

2 Vehicle Data |

MOTOR TRANSPORT

Minor

Van, Type 4 (Ford)

| 1. General -

This Instruction describes the Minor Van,

Type 4 (Ford). It is fully

interchangeable with other types of Minor

Van, the types of duties for which these

are intended being given in B 3550. 2. Description

- The vehicle is a modified Ford light

van of welded pressed-sheet-metal

construction. The overall dimensions are:

length 12 ft. 6 in., width 4 ft. 11 ¼

in. and height 5 ft. 4 ½ in.

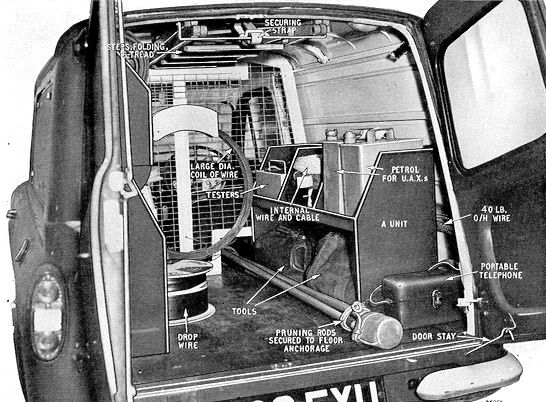

A general

view of the vehicle is shown in Fig 1.

Cab and body sections are separated by a

wire-mesh partition as shown in Figs. 2

and 3, to enable the body to be locked

without restricting access to the cab

(see par. 14). Accommodation is provided

externally for an extension ladder and

internally for a step ladder, pruning

rods, tools, stores, E.I.s etc. The rear

doors are fitted with hook and eye door

stays which should always be used when a

door is open to avoid minor accidents due

to doors swinging in the wind.

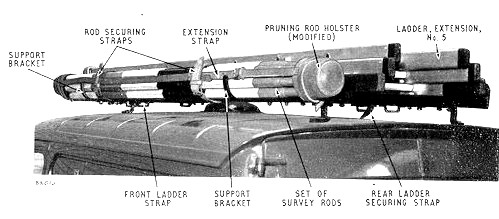

3.

Ladder carrier - A horizontal type of

ladder Carrier is provided on the roof

for a Ladder, Extension, No. 4, 4A or 5.

At the rear end of the carrier a roller

is fitted to facilitate the placing and

removal of the ladder.

|

The roller should

be oiled periodically to ensure smooth

and easy rotation. The ladder should be

secured at the front and the rear by the

straps provided for this purpose, and

should be so positioned that the ladder

does not overhang the rear of the

vehicle. To allow for the difference in

the bottom rung position on the various

types of extension ladders Nos. 4, 4A and

5, two sets of staples for anchoring the

ladder securing straps are fitted on the

ladder carrier. Only one extension ladder

of the specified type may be carried on

the ladder carrier and, except for the

special provision mentioned in pars. 11

and 12, nothing else may be carried on

the roof or on the ladder carrier. 4. Cab -

Seats in the cab provide for one

passenger in addition to the driver, the

driver’s seat being adjustable. Two

wire-mesh containers for E.I.s, log

sheets, diagram folders, works and other

papers are mounted on the wire-mesh

partition, one container being positioned

behind each seat. The vehicle tool box is

located immediately behind the

passenger’s seat.

A hat and

coat hook is provided in a central

position on the partition behind the

seats. The fire extinguisher is

accommodated in the cab.

|

Fig.

1

Fig.

2

| 5. Step ladder

accommodation - Steps, Folding,

5-tread (see par. 6) may be carried

within the body where they are secured by

a strap, in a central position

immediately under the roof (Fig. 2). The

aperture at the top of the partition,

through which the steps must pass, is

provided with a separate hinged wire mesh

panel as a security measure when steps

are not carried. To clear the aperture

for the accommodation of steps, only the

top fastening of the wire-mesh panel

should be undone; the panel will then

hinge downwards. When the folding steps

are being inserted, place the top of the

steps on the lower edge of the aperture

in the dividing partition; raise the

bottom of the steps as near to the

horizontal as possible and push them

forward until the top of the door framing

and the rear support for the steps can be

cleared; lift the bottom of the steps

fully up under the roof and pull the

bottom of the steps back into the rear

support; then fasten the steps securely

to the rear support with the strap

provided. The foregoing procedure should

be reversed to remove the steps. 6. Requisitions

for Steps, Folding, 5-tread for use on

these vans should be endorsed

‘Folding tread type required’.

|

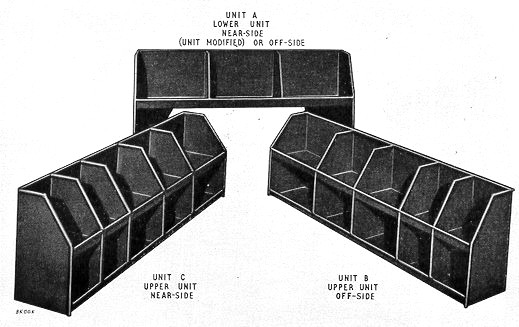

7. Rack units

- Accommodation for stores and tools is

provided by rack units which can be

fitted on either side of the interior of

the body and which are illustrated in

Fig. 5. When the van is supplied A units

only are fitted, the near-side unit being

modified to fit over the petrol tank

housing. B and C units are available as

optional fitments, being mounted on top

of the A units as shown in Fig. 2, using

the right-angle brackets which are

supplied with the vehicle. The brackets

supplied with the upper units should be

retained.

If, on certain duties, less rack

accommodation than the initial two A

units is required and extra clear floor

space is necessary, one or both A units

may be removed (see also par. 9).

Figs. 2 and 3 show a typical layout for

the load carried by a rural territorial

maintenance officer. Owing to the many

variations in the circumstances under

which minor-type vans may be employed it

is not practicable to lay down any

specific layouts. Much must be left to

the good sense of each officer concerned

in making the best use of the facilities

available. The principle of keeping heavy

items on the lowest level possible should

always be observed. Telephone

instruments, spare parts, cords, small

stores etc. |

| should be carried

in suitable cartons to prevent chafing

and rattling, and every effort should be

made to utilize the special containers

available for certain items, e.g. Gloves,

IR. and Dials, Automatic. 8. Supply of

additional rack units - When

additional units are required,

requisitions for Minor Van Fitting, Unit

A, B or C should be forwarded to the

Supplies Dept. On receipt of the

additional items an appropriate entry

should be made on the vehicle tool list

(A 1112).

9.

Recovery of rack units - Standard

units surplus to requirements should be

returned to the Supplies Dept. direct and

surplus modified A units scrapped

locally, the vehicle tool list being

amended accordingly. The special nuts

(Simmonds elastic stop nuts) provided for

the set screws securing the component

units together should not be used for

other purposes but should be secured to

their relevant units and returned,

together with the brackets originally

supplied with the B and C units, to the

Supplies Dept.

The top unit mounting brackets originally

supplied with the vehicle must be

retained on the vehicle to allow for

future changes in rack units requiring

their use.

|

10. Large

diameter coils of wire - A simple

saddle type of fitment mounted on the

rear of the vehicle cab/body partition is

provided as an aid to the tidy stowage of

large diameter coils of wire (Fig. 2). A

piece of twine or soft copper wire should

be used to secure the coil of wire to the

wire mesh of the partition and so prevent

chafing of the coil. 11. Pruning rods

- When pruning rods are carried they may

be placed on the floor of the vehicle,

their front ends being passed through the

aperture provided for this purpose in the

dividing partition (Fig. 3). The rear end

of the rods can then be secured to an

anchorage set in the vehicle floor beside

the rear support of the off-side A unit.

Alternatively, they may be carried on the

ladder carrier by means of brackets

bolted to the near-side of the ladder

carrier (see M 0048).

12.

Survey rods - Survey rods may be

carried on the ladder carrier in the same

manner as pruning rods (Fig. 4) but it is

essential that the set of survey rods be

equipped with the modified pruning rod

holster specified in M 0048, to ensure

that a rod cannot be dislodged in

transit.

|

Fig.

3

Fig.

4

Fig.

5

| 13. Maximum

permissible load - The maximum load

that a Minor Van, Type 4 (Ford) may carry

without any fittings is 5 cwt. 2 qrs. 17

lb. (this excludes the weight of the

driver, which has been taken as 168 lb.).

Hence, if a passenger (average weight 168

lb.) is carried when two A units (each

weighing approx. 34 lb.) are fitted, then

the total weight of tools, stores etc.

must not exceed 397 lb. The B and C units

each weigh 26 lb. and the load carried

must be reduced accordingly when these

units are fitted. A periodical

examination should be made by the driver

to ensure that surplus items are not

carried and that the maximum permissible

load is not exceeded. A simple check can

be made by weighing the van in its moving

condition, i.e. with driver, passenger,

stores, tools, racks, petrol, oil etc.

The gross moving weight must not exceed

22 cwt. 3 qrs. 9 lb. Any weighbridge

charges involved should be passed to

Freight and Cartage. 14. Locking

arrangements - Cab and rear doors are

equipped with FP 750 series locks to

enable the contents to be safeguarded

when the vehicle is left unattended for

short periods. For extended absences

additional security can be obtained by

padlocking the rear doors. A hasp and

staple are fitted to the rear doors for

this purpose. The vehicle tool box is

also equipped with a hasp and staple.

Padlocks, 1¼ in. are the correct

padlocks for use on this class of

vehicle.

|

[NOTE:-

Padlocks, 1¼ in. are sometimes of the

spring self-locking type. To prevent the

accidental locking of keys inside the van

body, it is recommended that the padlock

keys should not all be carried together.]

A spring clip is fitted on the rear door

to prevent chafing by the padlock.15. The spare

wheel - The spare wheel is housed

beneath the rear of the body floor in a

drop-front type of carrier which is

raised or lowered by rotating the

hexagonal head set in the rear off-side

of the floor (Fig. 2), using the wheel

brace.

16.

Towing - Minor Vans, Type 4 (Ford)

are not suitable for towing any type of

trailer or for use as a power unit to

assist working operations, and officers

are forbidden to use or attempt to use

the vehicle for these purposes.

17.

Re-enamelling or retouching - The

outside of the van has a synthetic enamel

finish. Attempts to retouch any scratched

or damaged parts should not be made by

the staff using the vehicle. Work of this

nature will be undertaken by the Workshop

Supervisor / Mechanic-in-Charge when

necessary and during periodic overhauls.

18.

Signwriting - Standard inscriptions

for signwriting are given in C 0015.

19.

Speed limit - See D 0022.

|

END

|

|

|