You are in:

Electrical

System |

General

Maintenance - Electrical System

| The electrical

system of the car consists of the 12-volt

generator, starter motor and ignition circuits,

which includes circuits for the fuel gauge,

horns, lights, indicators, and heater blower

motor (when fitted) and other accessories.The

complete car wiring circuit can be found here,

and shows the locations of the various electrical

units as can be visualised from a plan view of

the car. The Battery

The battery is a 12-volt lead acid type with nine

plates in each cell and a 38 ampere hour (51 AH

Special Equipment) capacity. The battery is

easily accessible by raising the engine bonnet.

The generator charging system is

automatically controlled to suit the needs of the

battery and, as a result, the battery should

seldom require any attention other than topping

up with distilled water. If however it does

become run down for any reason, it should be

recharged as a soon as possible;: it will

deteriorate if it is allowed to stand for any

length of time in a discharged condition.

The

positive terminal can be easily identified by an

embossed + (positive) mark adjacent to it. The

positive terminal base may also be red in colour.

When replacing the battery, always ensure that

the positive terminal is earthed to the body by

means of the short earth strap. (Warning –

If the vehicle has been changed to “Negative

Earth”, then please ensure that the earth

strap is attached to the – (negative)

terminal of the battery.)

It is most

important to ensure that the battery is firmly

secured and not allowed to shake loose in its

mountings. High resistances in the battery

circuit can also be caused by loose, dirty or

corroded battery terminals. Always keep the

connections clean and tight and the top of the

battery

|

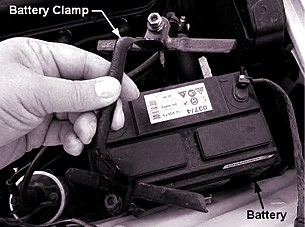

To Replace the Battery

To replace a failed or faulty battery, first

remove the leads from the battery terminals.

Unscrew the wing nuts on the battery clamp and

unclip the battery arms from the battery tray.

The battery can now be lifted out.Refit

the new battery, ensuring that the negative and

positive terminal posts are the correct way

around. Refit the battery clamp and battery

leads.

Warning

– Do not tip the battery over allowing the

electrolyte to discharge as this may cause

injury. Do not dispose of the old battery in your

refuse. Take it to your local Council Recycling

Centre.

|

|

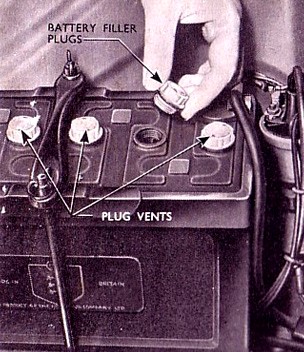

Check the Battery

Electrolyte Level - (Weekly Service)

The battery is

accessibly located under the bonnet, within the

engine compartment. Remove the filler caps and

check that the electrolyte in each cell is 1/4 to

3/8 in (6.35 to 9.525 mm) above the tops of the

plates. If below this level add distilled water

as necessary. (In cold weather the distilled

water should only be added immediately before

running the engine, so that when the generator is

charging, the water and electrolye will mix and

prevent freezing.) The filler caps can now be

refitted.Keep the battery filler

caps and battery connections tight and the top of

the battery clean. A coating of petroleum jelly

will protect the battery terminals. Occasionally

check the battery clamp to ensure that the

mounting wings nuts are tight and the battery is

still secure in the battery tray. Excessive use

of distilled water by the battery is usually an

indication of an unduly high generator-charging

rate and you should consult an Auto Electrician

and have the charging system checked.

|

|

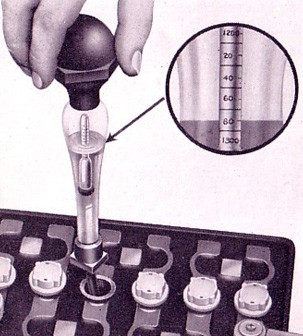

Battery Specific Gravity

The specific gravity is an indication of the

state of charge of the battery and should be

checked regularly with a hydrometer. The specific

gravity of the electrolyte of a fully charged

battery should be between 1.270 and 1.285 at 70º

F

When the acid temperature varies from 70º F a

correction must be made as follows:-

For every 10º F above 70º F, add 0.004 to the

specific gravity reading.

For every 10º F below 70º F, subtract 0.004

from the specific gravity reading.If

the level of electrolyte is so low that a

hydrometer reading cannot be taken, no attempt

should be made to take a reading until the

battery has been charging for at least an hour

after adding distilled water. This is to ensure

that the acid mixes thoroughly with the water to

form a uniform mixture. If the specific gravity

of the electrolyte is found to be low, the

battery should be recharged, preferably by your

Authorised Ford Dealer.

|

|

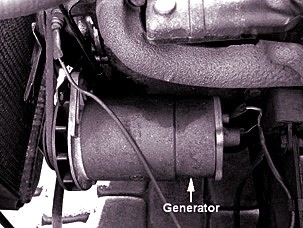

Generator (Dynamo)

A two-brush generator is mounted on the left hand

side of the engine and its output is

automatically controlled by a separate voltage

control regulator. If it is suspected that the

generator charge rate is not being regulated

correctly in accordance with the needs of the

battery, your Authorised Ford Dealer should be

allowed the check the regulator voltage and

adjust it if necessary. Periodically, it is

recommended that you have the generator voltage

checked with the aid of a master voltmeter. |

|

Cleaning

the Generator Commutator and Brushes

Occasionally, it may be necessary to clean the

commutator and brush gear. To do this, the

generator must be removed from the car and the

endplate withdrawn so that a thorough inspection

of the commutator can be made. If this latter

component requires attention, then the generator

will have to be further dismantled. If it is just

a matter of a greasy or dirty commutator, this

may be leaned with a petrol-moistened non-fluffy

cloth held lightly against the commutator whilst

the armature is being rotated.

If the commutator is found to be scored, take it

to your Authorised Ford Dealer, who has the

necessary equipment to restore the surfaces to a

good working condition without damaging the

segments. Never use emery cloth to clean the

commutator.Ensure that the bushes are

free to move in their holders. If the brushes are

found to be tight or sticking then they should be

drawn from their holders and the sides of the

brushes eased with a fine file.

If the brushes are exceptionally worn and reduced

in length, they should be renewed, as there would

otherwise be insufficient spring tension to keep

them pressed against the commutator.

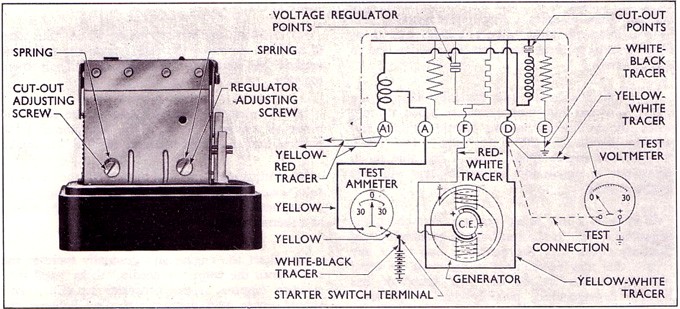

Voltage

Control Regulator

Starter

Motor

The starter motor is mounted on the right hand

side of the engine and is operated by a solenoid

switch mounted on the right hand side of the

engine bulkhead. Should it be necessary to rotate

the engine while working under the bonnet, this

may be achieved by pressing the rubber cap on the

starter switch after checking that the ignition

is “off” and the gear lever is in

neutral.

It requires no

attention beyond seeing that the cable

connections are clean and tight, the commutator

is kept clean and the brushes are renewed when

necessary. Should the need arise, the starter

pinion can be manually disengaged by removing the

starter motor end cap and turning the squared end

of the shaft.

|

Information taken from Various Ford

Anglia Instruction Books and Handbooks..

Warning -

The Health and Safety bit.

Please note your health may be at

risk if you do not take sensible safety

precautions. Never work under an unsupported

vehicle, do not take shortcuts. If you feel that

the task is beyond your capabilities, then employ

the services of a trained professional. The Owner

of this Website nor the author cannot be held

responsible for any accidents or injury arising

from advice given on this webpage. Safety advice

can be obtained from the RoSPA.

|

|

|